GasAbate manure management system

GasAbate is a liquid additive injected into slurry tanks using GlasPort Bio’s proprietary dosing and verification system. It is a globally patented, world-leading emissions-reduction system that has been developed from initial scientific research stage through to commercialisation by GlasPort Bio.

Independent trials have shown that GasAbate can reduce methane emissions from stored cattle and pig slurry by 80%, hydrogen sulphide by 80% and ammonia by 50%.

EXPLAINER

RTÉ News feature

THE DETAILS

GasAbate & emissions

Methane

Methane is a short-lived but highly potent greenhouse gas, with a global warming potential more than 80 times greater than carbon dioxide over a 20-year period. Globally, livestock manure management accounts for a significant share of agricultural GHG emissions. These emissions are primarily methane, released during anaerobic decomposition in slurry storage. Reducing methane emissions is now recognised as one of the most effective strategies for achieving near-term climate cooling.

GasAbate

GasAbate temporarily suppresses methanogens - the microbes responsible for methane production - by inducing a dormant state. This prevents the breakdown of organic matter during storage, effectively locking in the methane potential of the slurry and retaining crop nutrients. Unlike acidification, which permanently alters slurry chemistry, GasAbate’s effect is reversible. Once the additive degrades, microbial activity resumes, allowing the slurry to be used as a high-yield feedstock for anaerobic digestion (AD).

Proven results

GasAbate can reduce methane emissions from stored cattle and pig slurry by 80%. In intensive dairy systems, this equates to a reduction of nearly 1 tonne of CO₂-equivalent (CO₂e) per cow per year. On a 200-cow farm, that’s 200 tonnes of CO₂e annually - equivalent to the emissions from driving a diesel vehicle around the globe 185 times. In swine production, the impact is even more substantial. GasAbate has been shown to reduce emissions by 1.84 tonnes CO₂e per sow place per year, or nearly 1,000 tonnes CO₂e on a 500-sow unit.

THE DATA

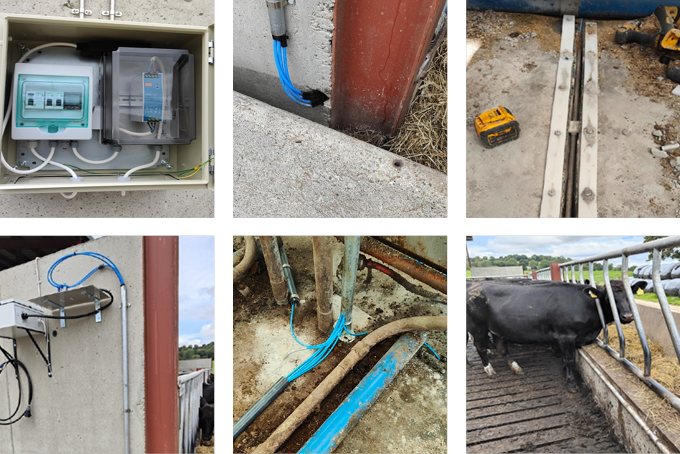

Automation & reporting

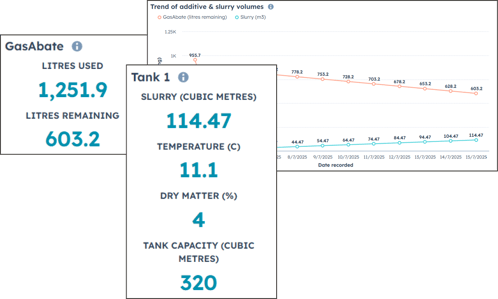

- GasAbate's on-farm sensors capture data on the amount of slurry being stored in tanks and its temperature.

- Depending on these readings, GasAbate liquid is added to the slurry automatically to reduce its emissions.

- When the additive is running low, an alert is triggered and a new delivery is arranged to keep things running smoothly.

- All of this information is passed to our bespoke cloud-based system daily for automated monitoring and reporting.

- With this data we are then able to report on the volume of slurry treated, additive used and emissions saved.

- These reports are then shared with our partners to allow them account for reduced emissions volumes.